MSU faculty use 3D printers to produce face shields for Meridian medical personnel

Contact: Philip Allison

STARKVILLE, Miss.—With personal protective equipment in short supply nationwide, a team of engineers and researchers at Mississippi State University is turning to an unlikely combination of 3D printers and office supplies to aid medical personnel tackling COVID-19.

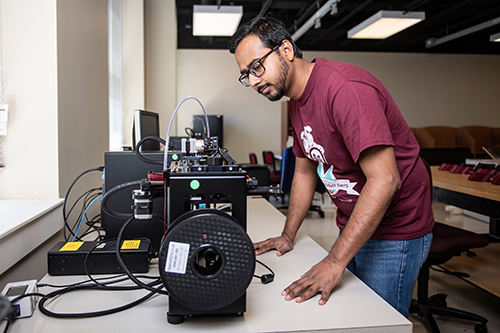

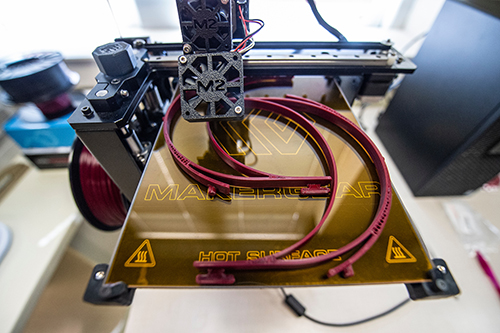

The team, led by faculty from MSU’s Bagley College of Engineering and researchers at the university’s Center for Advanced Vehicular Systems, is producing face shields by combining 3D-printed head bands with transparent plastic sheets and elastic bands generally found at office supply stores.

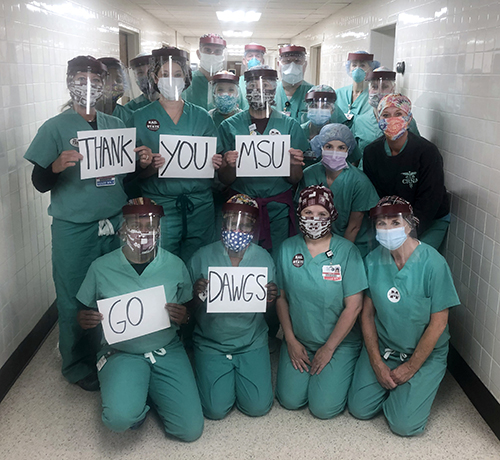

The head band for each face shield takes approximately two and a half hours to print. Using 10 different 3D printers, the team is producing approximately 250 shields per week using polylactic acid filament. The first batch was donated this week with over 100 going to both Rush Foundation Hospital and Anderson Regional Medical Center in Meridian, where they are being used by medical professionals caring for patients with coronavirus.

“We are in complete awe of the outpouring of support and donations we’ve received from residents and community businesses,” said Rush Health Systems Chief Executive Officer Larkin Kennedy. “The donation of these face masks from Mississippi State University helps ensure our front-line staff remains safe while caring for patients.”

“With PPE in short supply through our normal procurement channels, innovation has become a critical factor in making sure our staff and patients are protected. Many, many thanks to MSU’s faculty and researchers for developing a face shield that can be produced with easily obtainable supplies. Go dogs! Hail State! We are greatly appreciative of this donation which will go a long way in keeping Anderson staff members protected,” said John G. Anderson, President and CEO of Anderson Regional Health System.

Face shields are generally used in conjunction with surgical masks and protect the eyes, nose and mouth from splashes and sprays. The MSU team developed two prototypes before working with Kennedy to determine the best option for the Rush Foundation Hospital medical staff.

Working on the project are Linkan Bian, who holds the Thomas B. and Terri L. Nusz Professorship in industrial and systems engineering; Steve Elder, professor of agricultural and biological engineering; Wenmeng Tian, assistant professor of industrial and systems engineering; Tyler Hannis, research engineer at CAVS; and Abdullah Al Mamun, an industrial and systems engineering Ph.D. student from Bangladesh.

Bian said other university employees also have expressed interest in contributing to the project, including faculty and staff from both MSU’s College of Business and Mitchell Memorial Library.

“This has been a tremendous team effort so far,” Bian said. “We would not be able to move at our current pace without the efforts of Steve, Wenmeng and Tyler. We’ve also been contacted by others on campus who have 3D printing capacity, and they want to know how they can help. It is really encouraging.”

The project came about thanks in large part to research partnerships developed as part of Mississippi State’s Faculty Research Advisory Committee. When hospitals began to face shortages of personal protective equipment, Bian, a past chair of the group, contacted Carlton Young, professor of healthcare administration at Mississippi State’s Meridian campus and MSU-Meridian’s committee representative, to ask how he could help. Young connected Bian to representatives at area hospitals to launch the project.

“Dr. Bian reached out to me and said there was a group at Mississippi State that was willing to 3D print face shields for the hospitals in Meridian. They are now producing hundreds of them,” Young said. “Their expertise, public spirit and passion truly embody the heart of Mississippi State and our mission to serve the people of Mississippi.”

The Bagley College of Engineering is online at www.bagley.msstate.edu and can be found on Facebook, Twitter, Instagram and YouTube at @msuengineering. For more on CAVS, visit www.cavs.msstate.edu or find them on social media at @cavs_msstate.

Mississippi State University is Mississippi’s leading university, available online at www.msstate.edu.